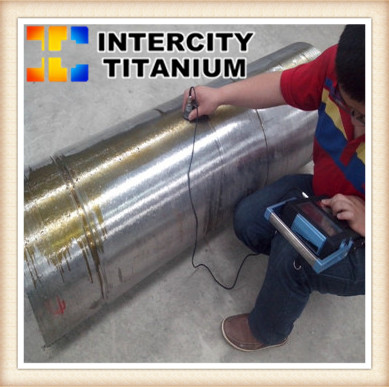

Ultrasonic flaw detection of titanium alloy forging

Titanium alloy has the following shortcomings: such as deformation resistance, poor thermal conductivity, gap sensitivity (1.5 or so), changes in microstructure of the mechanical properties of the significant impact, resulting in smelting, forging processing and heat treatment complexity The Therefore, the use of non-destructive testing technology to ensure that the titanium alloy metallurgy and processing quality, is a very important issue. In addition to the conventional forging ultrasonic flaw detection methods should pay attention to the problem, the titanium alloy forging ultrasonic flaw detection there are several issues to note.

Select the appropriate detection method

1. In order to ensure the quality of titanium alloy forging, in addition to strict control of the quality of raw materials, but also must be prevented in the follow-up hot process defects, should pay attention to forgings blank and semi-finished product ultrasonic testing, and the finished stage X-ray detection, Testing and anodizing corrosion and other means of inspection, the method of selection in principle with the general forging is basically the same.

2.The micro structural changes of titanium alloy forgings have a significant effect on the mechanical properties of the titanium alloy forging. The evaluation of the cluster level and the bottom wave loss in the ultrasonic flaw detection plays an important role in checking the uniformity of the titanium alloy.

The scattering of ultrasonography in the grain boundary and the intracrystalline phase structure may be shown by clutter on the phosphor screen, or it may be due to the decrease of the bottom wave height (bottom wave loss) caused by the attenuation of the acoustic energy, both of which have a certain Correspondence. According to the evaluation of these two parameters, has been found in coarse grains, parallel α organization (can cause low cycle fatigue performance Wei's organization) and so on.

In view of the current work, the microstructure of the titanium alloy with high clutter level is expressed as a complete and obvious primitive β grain boundary and a straight and elongated Wei 's α - structure (untransferable typical Wei' s organization), or Showing a large and large strip of α phase, such organizations in the mechanical properties of the performance indicators for the decline in strength. In addition, some casting tissue residues may also cause a higher level of clutter. But the general overheating Wei's organization, if the original β grain boundary and intramolecular phase orientation is more irregular disorder, although this organization is not good, even from the microstructure evaluation is unqualified, the clutter The level is not necessarily high, indicating that the level of assessment of the clutter there are still large limitations.

In the evaluation of the loss of the bottom wave, some of the Wechsian tissue on the high frequency components of the ultrasonic pulse have a more significant attenuation (such as parallel α organization), which is easier to observe in the spectrum analyzer, but the industrial production of large quantities of how to use ordinary ultrasonic flaw detector, select the best response frequency of the probe to detect the existence of some practical difficulties.

It should be pointed out that the current internal segregation of titanium alloy forging is also no reliable and effective ultrasonic detection method.

In general, how to use ultrasonic waves to respond to a variety of different microstructures to control the quality of titanium alloy performance is the subject of in-depth research (such as the use of higher, even hundreds of megahertz frequency, and the use of electronic computer information processing Wait). Nevertheless, in the current titanium alloy forgings and materials for ultrasonic testing, the cluster level and bottom wave loss assessment are still two very valuable indicators.

3. Ultrasonic flaw detection of titanium alloy forging materials, sometimes due to a single large grain or local tissue irregularities caused by tissue reflection will appear in the form of a single reflection signal, easy and real metallurgical defects (such as high density inclusions, cracks, Holes, etc.) of the reflected signal is confused, through the experimental analysis that this reflection signal may be due to the ultrasonic reflection of the phase caused by the superposition. In this case, the use of a small diameter probe or focus probe (reduced beam diameter) to improve the ultrasonic frequency, with the same detection sensitivity (flat bottom hole diameter of the same test block) re-assessment, you will find the reflected signal amplitude decreased significantly, Sometimes even disappear, while the real metallurgical defect of the reflected signal in this case will not change significantly. This method can identify actual metallurgical defects and tissue reflections in titanium alloys.

Of course, in the ultrasonic testing of titanium alloy forging, and other materials, such as ultrasonic testing, attempt to only A-type reflection pulse signal to determine the nature of the defect is clearly not possible, must be combined with the specific characteristics of the object of the material, smelting And forging processing technology, and supplemented by other non-destructive testing methods (such as X-ray photography, penetration, ultrasound C-scan, etc.), coupled with the level of experience of the flaws of their own comprehensive analysis to determine, if necessary, anatomical validation (including Macro, high power, and even electron microscopy, electronic probe and other means). Therefore, the current titanium alloy forgings and ultrasonic testing of raw materials, the quality of the acceptance criteria is basically still based on the parameters of the echo signal.