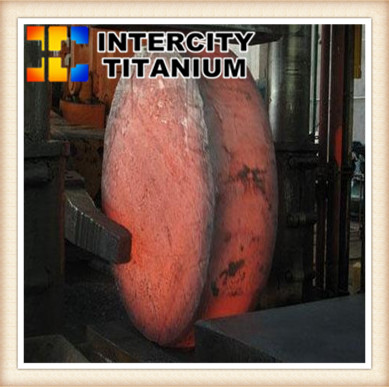

Titanium sponge after the melting of the ingot organization for the coarse as-cast structure, this coarse columnar casting mechanical properties of poor, affecting the use of titanium, titanium alloy ingots need to go through forging deformation and heat treatment, in order to obtain the ideal Organizational morphology, change the microstructure and properties of the alloy.

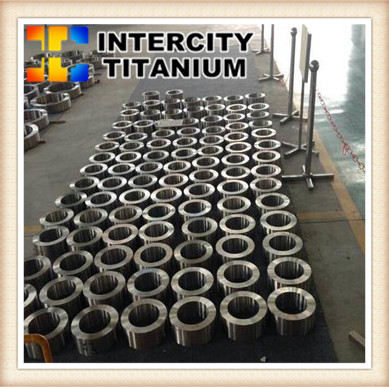

Titanium forging is one of the metal pressure processing methods. Refers to the forming method for the production of mechanical parts, workpieces or blanks by applying pressure to the blank to produce plastic deformation, changing the size, shape and improving the functioning of the machine. Titanium and titanium alloy forging products are bar, cake, ring material, special-shaped forgings and other finished products and slabs and extruded billet and other blank.

The advantages of titanium forging production are: not only can get the shape of metal parts, but also to improve the original metal structure, improve the mechanical properties of metal and physical properties. Generally for the major mechanical parts of the main force, most of them are manufactured by forging method.

Titanium forging can be classified according to forge process, forging method, forging equipment and forging temperature. The use of which forging method is mainly based on the shape of the formed product, microstructure and mechanical properties of the requirements to decide.

Titanium and titanium alloy forging according to the use of equipment and tools are generally divided into the following categories.

1 free forging (commonly known as free forging) is a titanium forging between a heated metal blank placed between the flat anvil of a free forging device or between simple tools, and the deformation is characterized by the use of a hammer or a hammer on a forging hammer or press The anvil is moved up and down so that the billet (or blank) is compressed in the height (thickness) direction and is freely stretched (stretched) in the horizontal direction to obtain a product conforming to the shape and size requirements. Free forging with the benefits of simple equipment, low cost, good production flexibility. So it is titanium and titanium alloy billet, forging bar, cake and ring material and other basic methods.

2 model forging (commonly known as forging), is to heat the metal blank placed in the die forging equipment within the mold for titanium forging, by the mold to limit the deformation of the metal, so as to obtain the same shape with the mold forging. Depending on the deformation of the hot, forging for the open forging and closed forging.

3 tire mold forging (commonly known for tire forging) refers to the free forging to the model forging the deformation of the way, is the heating of the metal with a free forging method forging about the shape of titanium forging, and then in the free forging machine with tire mold end Forging shape. The tire mold is a type of not fixed in the free forging equipment, relying on the anvil to transfer hammer gi of the single mold cavity mold.

4 special forging, which is a new process of modern development, that is, in a special equipment or special mold within the metal blanks forming a special forging method, the general forging method is difficult or impossible to obtain titanium forging can be used for special forging. Such as precision forging (commonly known as precision forging), such as heating set up.